- We have the ability to transfer sheet goods between any store and also to your job site.

- Need to order large amounts of Sheet Goods? Sheet Goods are also stocked in our Corona, CA bulk yard. The Corona location has a minimum order of 15 sheets and is open to the public by appointment only.

- Looking for something else? Click to learn about our Hardwood & Softwood Panels along with our Melamine Panels.

- Still don’t see what you are looking for or need more information? Call us at (714) 632-1988 or drop us a link via the Contact Us page.

Plywood Frequently Asked Questions

What Is Plywood?

Plywood is an engineered wood product typically consisting of three to seven layers of thin sheets of wood veneer that are then glued together. Each veneer is laid with its grain at a right angle to the last (or tighter angles such as 45 degrees in some plywood). This is done to create a product with high dimensional stability that resists splitting and warping.

What Do The Different Plywood Grades Mean?

Plywood is graded A-D (best to worst) for its front face and 1-4 (best to worst) for its back. A1, A2, B1, and B2 are acceptable for applications where both sides will be seen, while A4 or B4 would be fine for projects where the back will not show.

What Are The Different Core Types?

The core is any substrate that has a wood veneer ply on the face and/or back applied to it with an adhesive. There are many different types of cores, including medium-density fiberboard (MDF), veneer core, pro-core and particleboard core.

MDF

Medium Density Fiberboard Core has the most uniform thickness and consistency of any panel core. MDF sheet goods are usually used in interior projects as the core is more susceptible to moisture than other cores. MDF panels should be reinforced if the project requires a lot of weight to be placed on the sheets. MDF takes paint exceptionally well.

Ultralight MDF

Ultralight MDF is a medium density fiberboard that weighs about 30% less than standard MDF. Manufactured in Chile from 100% radiata pine, it features an even density profile and a smooth, flawless surface. MDF is ideal for furniture components, doors, millwork, displays, store fixtures, cabinets, picture frames and more.

Pro-Core (Sometimes Called Combination Core)

Pro-Core uses MDF crossbands and a veneer core interior to deliver an exceptional performance. The MDF face and back offers are great laminating surface, and the veneer core delivers fantastic physical properties at a lighter weight.

Particle Board Core

Particle board core provides the perfect density on the face and back to accept laminates of all kinds, and a core that delivers physical properties to make it a workhorse for many applications. It is the weakest plywood core option (although still denser than solid wood) and does not hold screws as well. PBC is also heavy (a 4×8 panel weights approximately 100 pounds) and swells up when exposed to moisture. It does offer a more uniform texture than veneer core plywood, creating a smooth void-free surface for veneer.

Veneer Core

A Veneer Core is plywood in which all the plies are made of veneers orientated with their plane parallel to the surface of the panel. Veneer Cores are constructed using innerplies typically composed of western softwoods. These core panels are lightweight, dimensionally stable and have excellent screwholding capacity. Typically a 3/4″ panels weighs around 70 lbs.

Types of Cuts

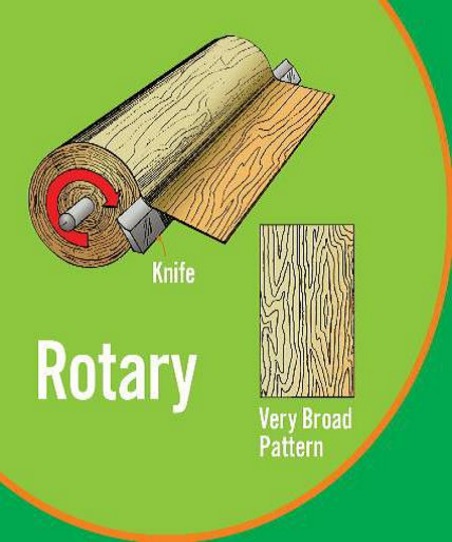

Rotary: The log is centered in the lathe and turned against a knife blade at a slight angle following the log’s annular growth rings, producing a multi-patterned grain veneer. Ideal for: Large surface applications where a broad grain pattern will suffice. Rotary cut sheets are generally less expensive than sliced veneer and can yield whole piece face sheets.

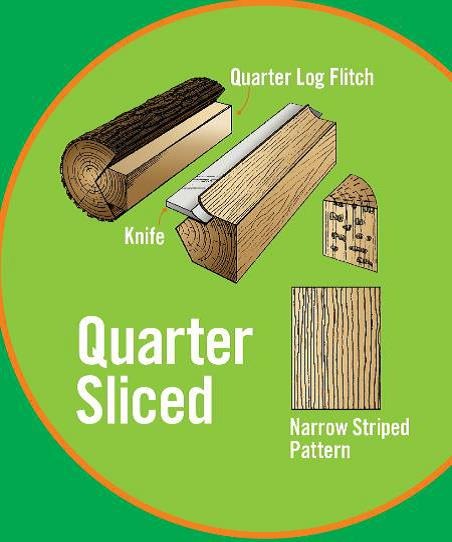

Quarter Slicing: Produces a narrow, striped grain veneer where the growth rings of the log strike the blade at approximately right angles. Some species will create a series of straight stripes, while others’ stripes may be varied in angle and length. Red and white oak produce a pronounced flake pattern when quarter sliced, while mahogany creates a ribbon stripe pattern. Ideal for: Mission-style or other applications requiring a uniform appearance with generous ray flaking. More cost-effective than rift-cutting.

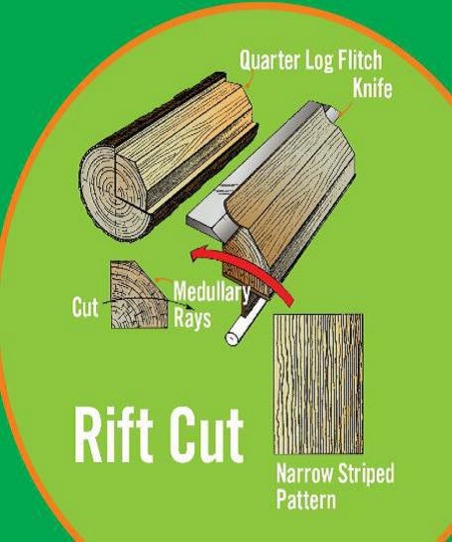

Rift Cut: Produces a rift or comb grain effect similar to that of quarter slicing, but generally is only used with red and white oak. This process minimizes ray flake as the log is cut at an angle of about 15 percent off the quartered position. Ideal for: An application calling for uniform white or red oak appearance without ray flake. Generally higher in cost due to low yields.

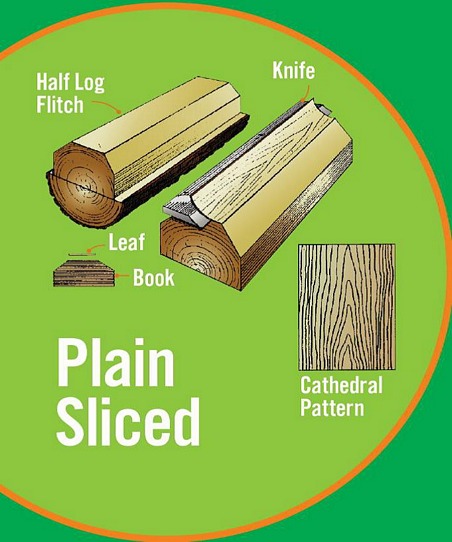

Plain Sliced AKA Flat Cut: The most common slicing method that produces a distinct cathedral grain veneer. A half log, or flitch, is mounted so that the veneer is cut along the growth rings, parallel to a line through the center of the log. Ideal for: Any application where an eye-catching pattern is desired at an affordable cost; of the slicing methods, plain slicing is the least expensive.

Example Of Cores

Beaded MDF

| Thickness | Type | Size | Core | SKU | Location |

|---|---|---|---|---|---|

| 1/4

1/4 1/4 |

Beaded 2”

Beaded 3” Beaded 4” |

4X8

4X8 4X8 |

MDF

MDF MDF |

56372

56373 56374 |

Anaheim & Riverside

Anaheim & Riverside Anaheim |

Hardboard

| Thickness | Type | Size | Core | SKU | Location |

|---|---|---|---|---|---|

| 1/8

1/8 1/4 |

Standard Hardboard

Tempered Hardboard Tempered Hardboard |

4X8

4X8 4X8 |

N/A

N/A N/A |

56061

56051 56052 |

Anaheim & Riverside

Anaheim & Riverside Anaheim & Riverside |

Medex

| Thickness | Type | Size | Core | SKU | Location |

|---|---|---|---|---|---|

| 1/2

3/4 1 |

Medex (Moisture Resistant)

Medex (Moisture Resistant) Medex (Moisture Resistant) |

4X8

4X8 4X8 |

Medex

Medex Medex |

56504

56506 56508 |

Anaheim

Anaheim Anaheim |

Medium Density Fiberboard

| Thickness | Type | Size | Core | SKU | Location |

|---|---|---|---|---|---|

| 1/4

3/8 1/2 5/8 3/4 1

1/4 1/2 3/4 |

MDF

MDF MDF MDF MDF MDF

MDF MDF MDF |

4X8

4X8 4X8 4X8 4X8 4X8

4X10 4X10 4X10 |

MDF

MDF MDF MDF MDF MDF

MDF MDF MDF |

56302

56303 56304 56305 56306 56308

76302 76304 76306 |

Anaheim & Riverside

Anaheim & Riverside Anaheim & Riverside Anaheim Anaheim & Riverside Anaheim

Anaheim Anaheim Anaheim |

Medium Density Fiberboard (Ultralite)

| Thickness | Type | Size | Core | SKU | Location |

|---|---|---|---|---|---|

| 1/2 (12mm)

5/8 (15mm) 3/4 (18mm) 1 (25mm)

3/4 (25mm) |

MDF Ultralite

MDF Ultralite MDF Ultralite MDF Ultralite

MDF Ultralite |

4X8

4X8 4X8 4X8

4X10 |

MDF Ultralite

MDF Ultralite MDF Ultralite MDF Ultralite

MDF Ultralite |

56394

56395 56396 56398

76396 |

Anaheim & Riverside

Anaheim Anaheim & Riverside Anaheim

Anaheim |

Particle Board

| Thickness | Type | Size | Core | SKU | Location |

|---|---|---|---|---|---|

| 1/2

3/4

3/4 |

Particle Board

Particle Board

Particle Board |

4X8

4X8

4X10 |

Particle Board

Particle Board

Particle Board |

56404

56406

76406 |

Anaheim

Anaheim & Riverside

Anaheim |

About Reel Lumber

Reel Lumber Service is a 4th generation family owned and operated hardwood lumber company established in 1932. We are committed to being the preferred supplier of quality lumber materials to our family of customers in the Southern California community.

In addition to our hardwood and softwood lumber yards we also own and operate Regal Custom Millwork. Regal Mill now provides lumber milling services and custom details to our customers’ specifications, as well as milling and manufacturing lumber and stock mouldings for Reel Lumber Service.

Door to door delivery of hardwood, sheet goods and mouldings are available. With multiple service trucks we’ve got you covered. For large orders there is no fee for delivery.

From a small lumberyard in 1932 stocking 10 species of lumber, Reel Lumber Service has grown to four locations, stocking over 40 domestic and exotic hardwood lumber species. We now offer a full selection of hardwood mouldings, MDF mouldings, plywood and various sheet goods, as well as a number of finishing materials, tools and other woodworking related items. We are a professional lumber distributor and we’d love to be the wood supplier for your current and future projects. Give us a ring at (714) 632-1988 or use the Contact Us form and we’ll gladly supply you with information about products, prices and delivery.

Due to industry trends and availability, items and species are subject to change without notice.

This product can expose you to chemicals including wood dust which are known to the State of California to cause cancer, and methanol, which are known to the State of California to cause birth defects or other reproductive harm. Drilling, sawing, sanding or machining wood product can expose you to wood dust. Avoid inhaling wood dust or use a dust mask or other safeguards for personal protection. For more information, go to www.p65warnings.ca.gov and www.P65Warnings.ca.gov/wood.